After several months of careful preparation, design and construction, we have successfully completed the ballast water treatment system aboard ship conversion project of VLOC, a well-known foreign bulk cargo shipowner. On the basis of ensuring the normal loading and unloading of the ship, the program also saves the cost of entering and maintaining the plant, docking fees/docks, etc., enhances the market competitiveness of the ship, and makes a positive contribution to Marine environmental protection!

In this project, instead of upgrading the original ballast water system of the ship in the shipyard in the past, through close cooperation and full communication with the ship management team, a comprehensive modification plan of the ballast water treatment system on board the ship was developed. This scheme not only saves the refit cost for the shipowner, but also improves the market competitiveness of the ship and ensures the normal navigation and loading and unloading operation of the ship.

The modification plan was upgraded and discussed several times

Because the ship itself has installed a set of ballast water treatment system, but because of frequent system failures, the owner finally decided to replace the equipment brand with low operating costs, low failure rate and easy maintenance.

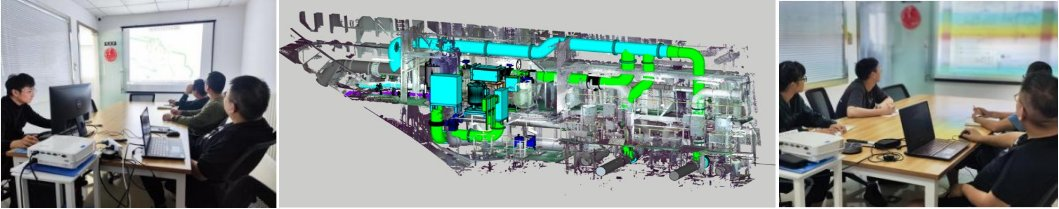

After a thorough inspection and evaluation of the original ballast water treatment system, the design team determined the sequence of removal of the old equipment and the necessary safety safeguards. At the same time, according to the evaluation results, a number of design upgrades of the system were carried out, including rebuilding the pipeline direction, increasing the processing capacity, improving the filtration effect, updating the equipment and increasing the automation control. Ensure that on the basis of perfect design, reduce the construction workload as much as possible, shorten the construction time.

Disassembly of old equipment.

In the prefabrication of pipeline and base support, the most advanced welding equipment, equipped with the latest technology and technology, skilled welding team, to achieve high precision, high quality welding and efficient production process, to ensure the accuracy of each pipeline, weld safety and timely delivery ability, to avoid the modification of construction volume along with the voyage process. Help shipowners to reduce costs while strictly controlling quality and shorten construction time.

Pipe support prefabrication

In the construction team, the use of experienced, skilled professional ship construction team, adhere to strict quality management standards to ensure that the project meets the relevant norms and standards. In the construction process, we strictly abide by the relevant safety regulations and environmental requirements, and take a series of measures to ensure the safety and sustainability of the site. At the same time, we can effectively formulate detailed construction plans, arrange construction procedures, solve difficulties in time, and ensure timely delivery of projects.

On-site construction during sailing

During the refit process, we have maintained close cooperation and communication with the shipowner and ship management team to solve problems and adjust plans in time. Through close cooperation with all parties, the modification work was successfully completed, and underwent strict testing and verification to ensure the stability and reliability of the system. Finally, it was highly recognized by the on-site surveyor and the shipowner, and ensured that the equipment passed the one-time successful inspection.

Site commissioning inspection

Through the optimization of the design scheme, the filtration effect of the equipment is improved, the maximum processing capacity of the equipment is satisfied, and the ship can be completed in the shortest time when unloading the cargo, so as to improve the transportation efficiency of the ship.

At the same time, in order to facilitate the operation of the crew and ensure the stability of the operation of the equipment, the transformation and integration of all the system related valves have been carried out, and the centralized remote operation of the central PLC has greatly reduced the work intensity of the press and discharge load, and ensured the safety and efficiency of the ship's cargo control operation.

After the installation was completed, the crew was systematically trained and instructed to ensure that they could properly operate and maintain the new system. We will continue to maintain close contact with them so that we can provide technical support and answers to questions at any time.

The system is installed after completion

The successful completion of the project has helped the shipowner to improve the transportation efficiency of the ship and reduce the operating cost of the ship. Thanks to all colleagues for their support and help in this project, and also thanks to the trust and cooperation of the ship owner and ship management, which has laid a solid foundation for the smooth completion of this transformation!

Everglory will always be committed to providing more advanced, more reliable and more optimized solutions for the shipping industry, and contribute to the sustainable development of ship operations.